February 4, 2026

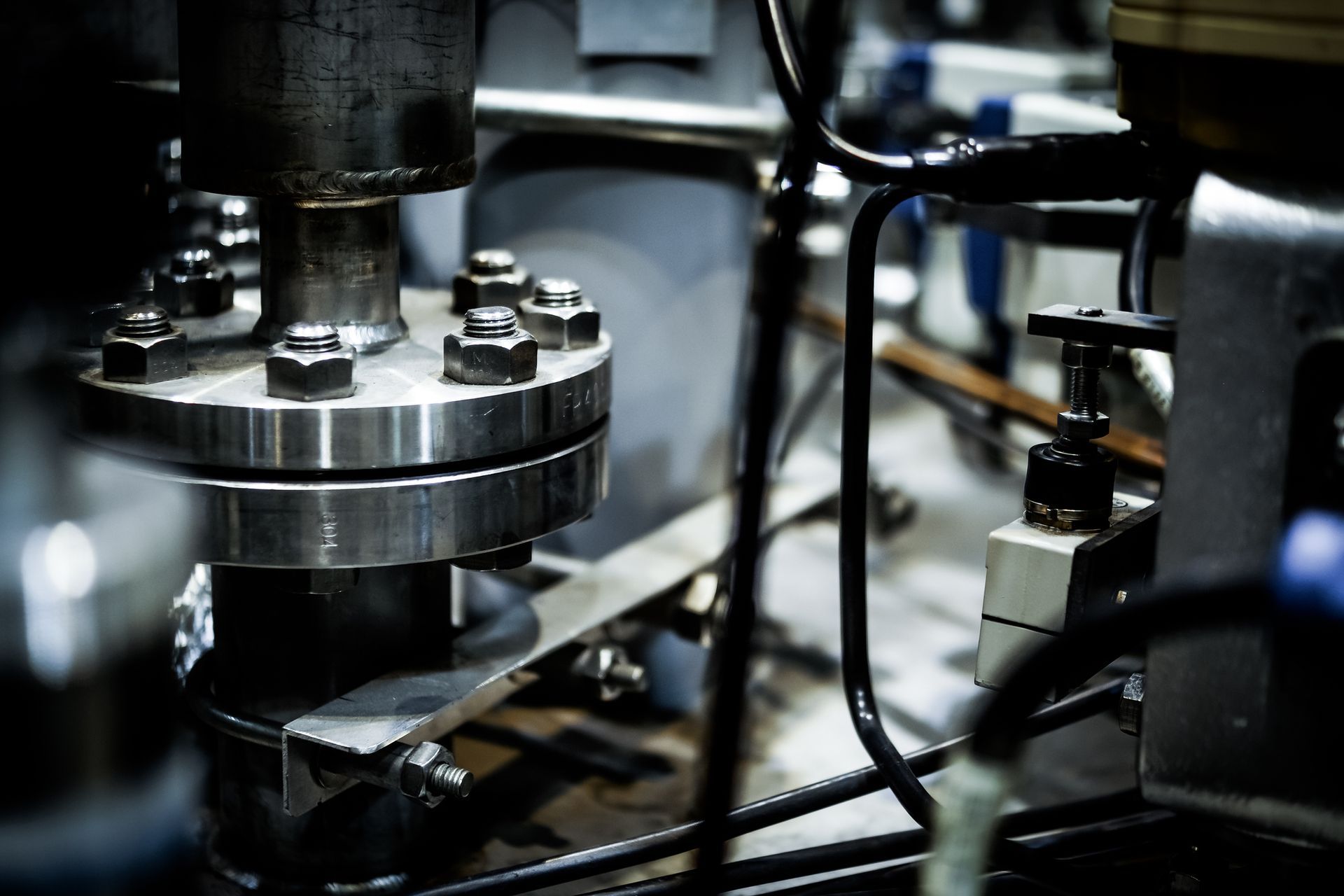

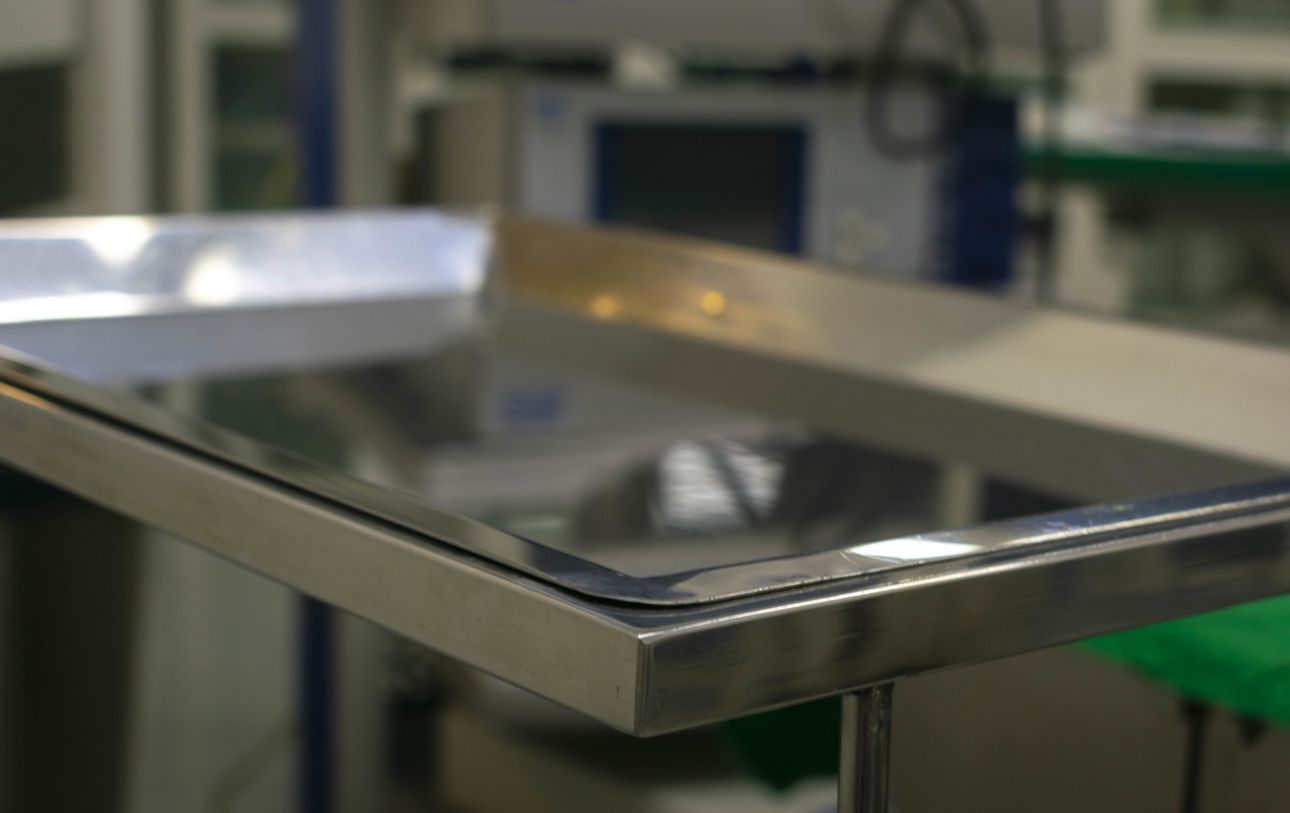

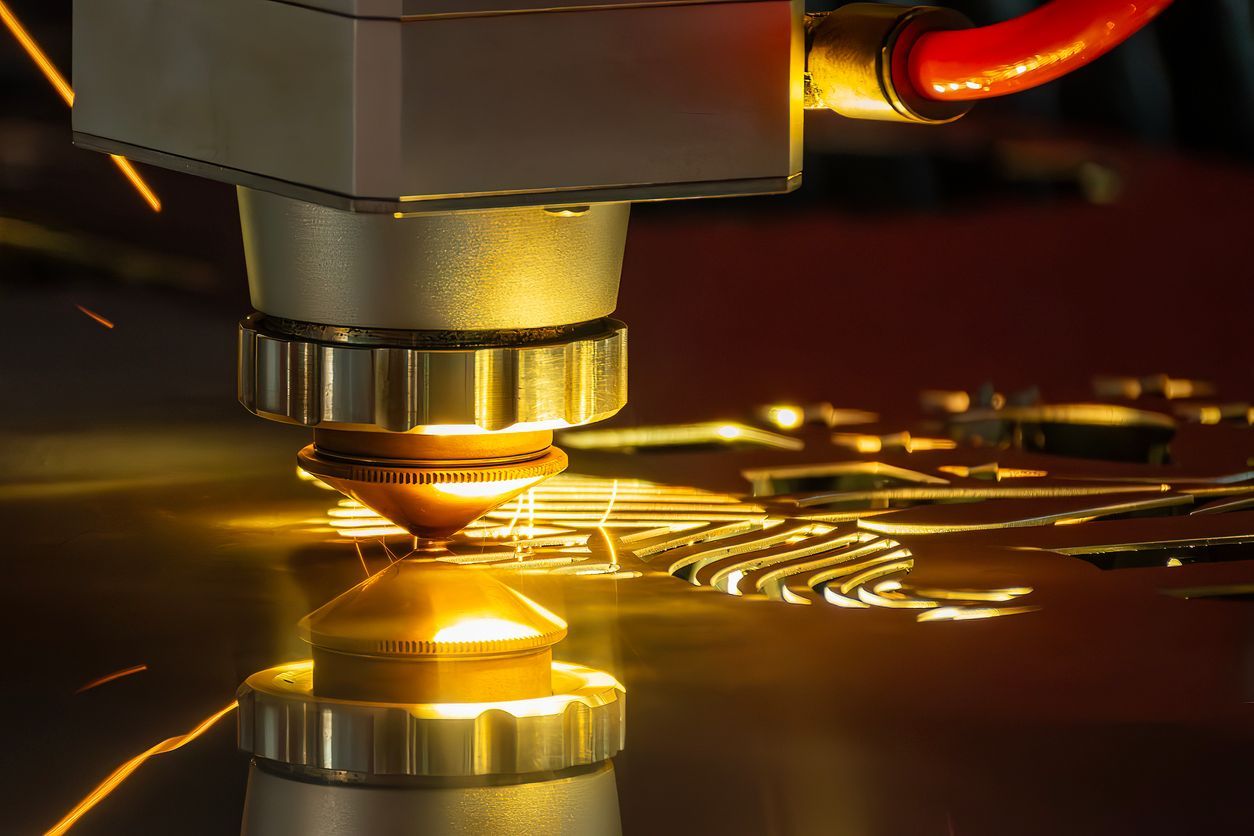

In healthcare and laboratory environments, every detail matters. From infection control to workflow efficiency, the equipment and workspaces used every day need to be reliable, easy to clean, and built to perform under constant use. That is why precision fabrication is so important. When stainless steel casework, countertops, sinks, shelving, and custom components are fabricated with accuracy and consistency, it helps facilities operate safer, cleaner, and more efficiently. Here are the top 5 benefits of precision fabrication in healthcare and laboratory settings - and why it is worth investing in quality from the start. 1) Better Hygiene and Easier Cleaning Hospitals, clinics, and labs have strict cleanliness standards for a reason. A workspace that is difficult to clean can quickly become a problem. Precision fabrication helps support hygiene by providing: Smooth, clean welds with fewer crevices Tight seams that reduce bacteria buildup Consistent edges and corners that are easier to wipe down Stainless steel surfaces that handle frequent cleaning and disinfecting When equipment is built correctly, cleaning teams and staff can do their jobs faster and more thoroughly, with less risk of contamination. 2) Improved Safety for Staff and Patients Healthcare and lab workers rely on equipment that is safe and stable. Poorly built metalwork can create hazards like sharp edges, uneven surfaces, or weak joints. Precision fabrication reduces safety risks by ensuring: Clean edges with proper finishing Secure welds that hold up over time Proper fit and alignment of doors, drawers, and panels Stable support for heavy instruments and supplies When equipment is built to spec, staff can focus on their work instead of worrying about equipment failure or injury. 3) Stronger Durability for High-Use Environments Healthcare and laboratory facilities are demanding. Surfaces are used constantly, and equipment is often exposed to moisture, chemicals, and heavy daily traffic. Precision fabrication helps create long-lasting solutions that can handle: Daily wear and tear Frequent sanitizing and chemical exposure Heavy storage loads and repeated opening/closing The need for consistent performance over years of use Investing in well-built stainless steel fabrication often means fewer repairs, fewer replacements, and less downtime. 4) Exact Fit for Specialized Spaces and Equipment Most labs and medical facilities are not "one size fits all." Many rooms have tight layouts, existing utilities, or unique equipment requirements. Precision fabrication makes custom solutions possible, including: Stainless steel countertops and workstations built to exact dimensions Custom sinks, drainboards, and backsplash designs Casework designed around plumbing, electrical, and ventilation needs Specialty cutouts for equipment, fixtures, and access points When components are fabricated accurately, installation is smoother and the final workspace looks cleaner and functions better. 5) Better Workflow and Efficiency In healthcare and laboratory settings, efficiency is not just a convenience - it can impact patient care and lab turnaround time. Precision fabrication supports better workflow by allowing facilities to design spaces that: Improve organization and storage access Reduce clutter and wasted movement Keep tools and supplies within reach Create clean, functional work zones for staff Well-designed, properly fabricated equipment can help teams work faster and stay more organized during busy shifts. Why Stainless Steel Is Often the Best Choice While different projects may require different materials, stainless steel is a top choice for healthcare and labs because it is: Corrosion-resistant Non-porous and easy to sanitize Durable under heavy use Professional in appearance Ideal for sterile and controlled environments When fabricated with precision, stainless steel becomes an even stronger long-term investment. Final Thoughts: Precision Matters in Critical Environments In healthcare and laboratory settings, quality fabrication is not just about looks - it is about performance, safety, cleanliness, and reliability. Precision fabrication helps facilities reduce risk, improve workflow, and maintain the high standards required in medical and lab environments. If you are planning a new build, renovation, or equipment upgrade, working with an experienced metal fabrication shop can make all the difference. Need Custom Fabrication for a Healthcare or Lab Project? If your facility needs custom stainless steel fabrication, casework, countertops, or specialty components built with accuracy and care, Silvey Metalworks is here to help.