Designing Durable Lab Workspaces: Why Stainless Steel is the Gold Standard

Stainless Steel Laboratories

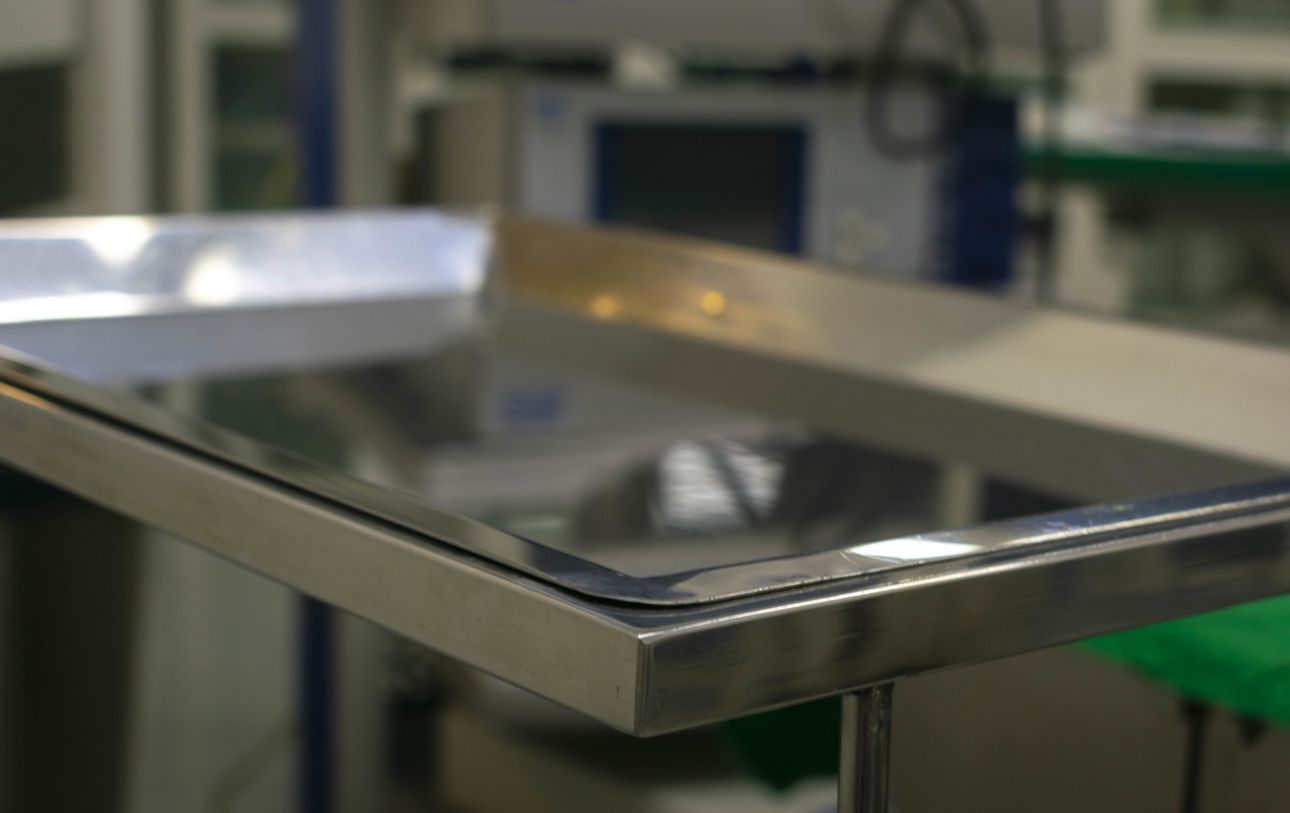

When it comes to designing laboratory workspaces—whether in schools, hospitals, or research facilities—durability and cleanliness are top priorities. Every detail, from the countertops to the sinks and storage units, must withstand rigorous use and frequent sanitation. That’s why stainless steel has become the gold standard for lab design, offering unmatched performance, longevity, and safety.

At Silvey MetalWorks in Chattanooga, TN, we specialize in custom stainless steel fabrication for laboratories, medical facilities, and commercial spaces—crafting solutions that meet the highest industry standards while fitting each client’s unique needs.

1. Built for Strength and Longevity

Laboratories are high-demand environments where work surfaces endure constant exposure to chemicals, heat, and heavy equipment. Stainless steel’s resistance to corrosion, impact, and temperature changes makes it one of the most durable materials available. Unlike wood or laminate, it won’t warp, crack, or stain—ensuring your workspace remains in top condition for years to come.

2. Hygienic and Easy to Clean

In any lab setting, cleanliness is critical. Stainless steel’s non-porous surface prevents bacteria and contaminants from seeping in, making it exceptionally hygienic. It’s also simple to sanitize, standing up to strong disinfectants and frequent cleaning without degrading or discoloring. This makes stainless steel an ideal choice for medical, pharmaceutical, and educational laboratories where sterile conditions are a must.

3. Precision Meets Customization

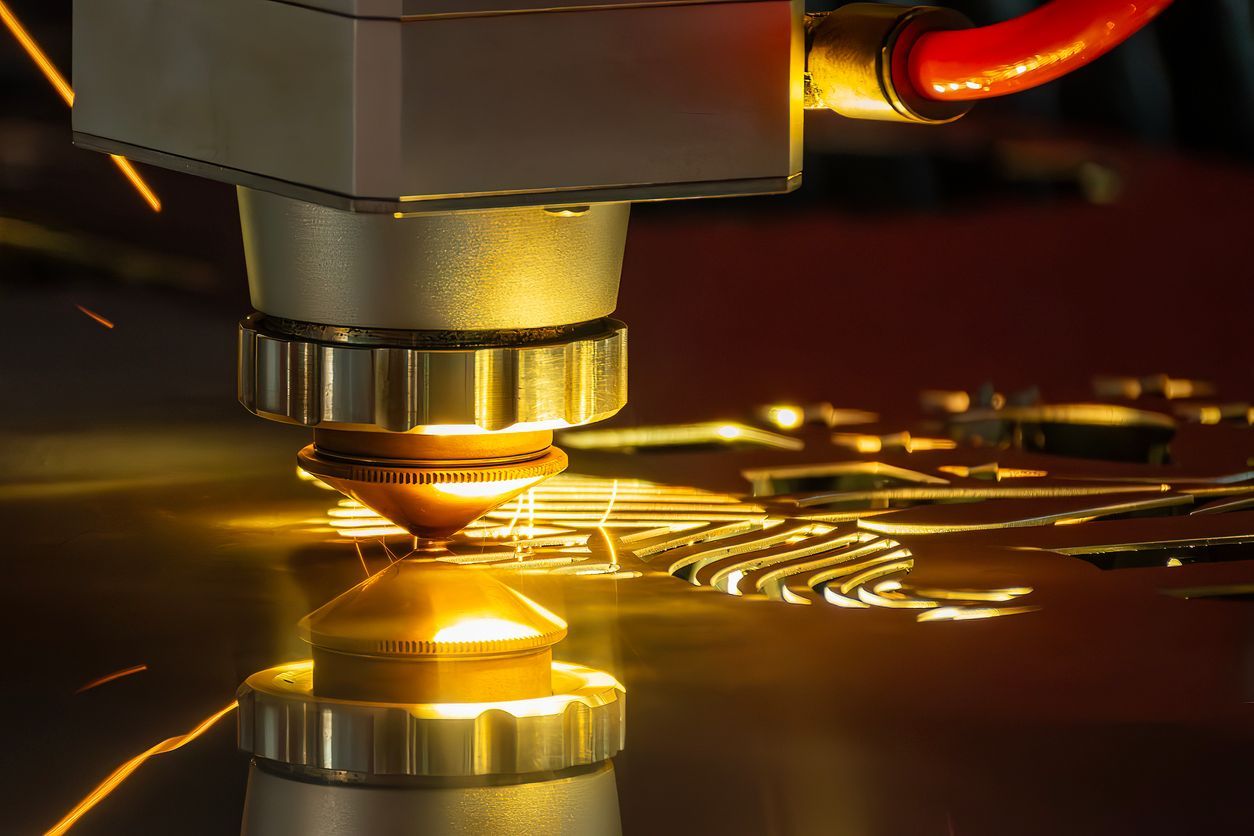

Every laboratory has different workflows, equipment, and safety requirements. With custom metal fabrication from Silvey MetalWorks, you’re not limited to standard configurations. Our team designs and fabricates custom stainless steel tables, countertops, sinks, shelving, and cabinetry to fit your exact specifications—creating a seamless, efficient workspace that enhances productivity and safety.

From integrated sinks to welded backsplashes and reinforced tops, every piece is built to perform under pressure.

4. A Sustainable and Cost-Effective Choice

While stainless steel may cost more upfront than other materials, its longevity and recyclability make it a cost-effective and environmentally responsible investment. Because it rarely needs replacement and can be fully recycled at the end of its lifecycle, it’s a smart choice for organizations focused on sustainability and long-term value.

5. Versatility Beyond the Lab

At Silvey MetalWorks, our stainless steel expertise extends beyond laboratories. We also design and fabricate for commercial kitchens, outdoor cooking spaces, medical facilities, funeral homes, and more. No matter the environment, stainless steel’s durability and clean aesthetic make it a practical and professional choice.

Partner with Silvey MetalWorks

When you choose Silvey MetalWorks, you’re partnering with a team that understands both form and function. Our custom metal fabrication services in Chattanooga, TN combine advanced craftsmanship with precision engineering to deliver results that stand up to the demands of your workspace.

Let’s create a lab environment that’s built to last—clean, durable, and designed for excellence.

Contact Silvey MetalWorks today to discuss your custom stainless steel fabrication project.