Outdoor Kitchen Trends in 2025: Stainless Steel, Style, and Durability

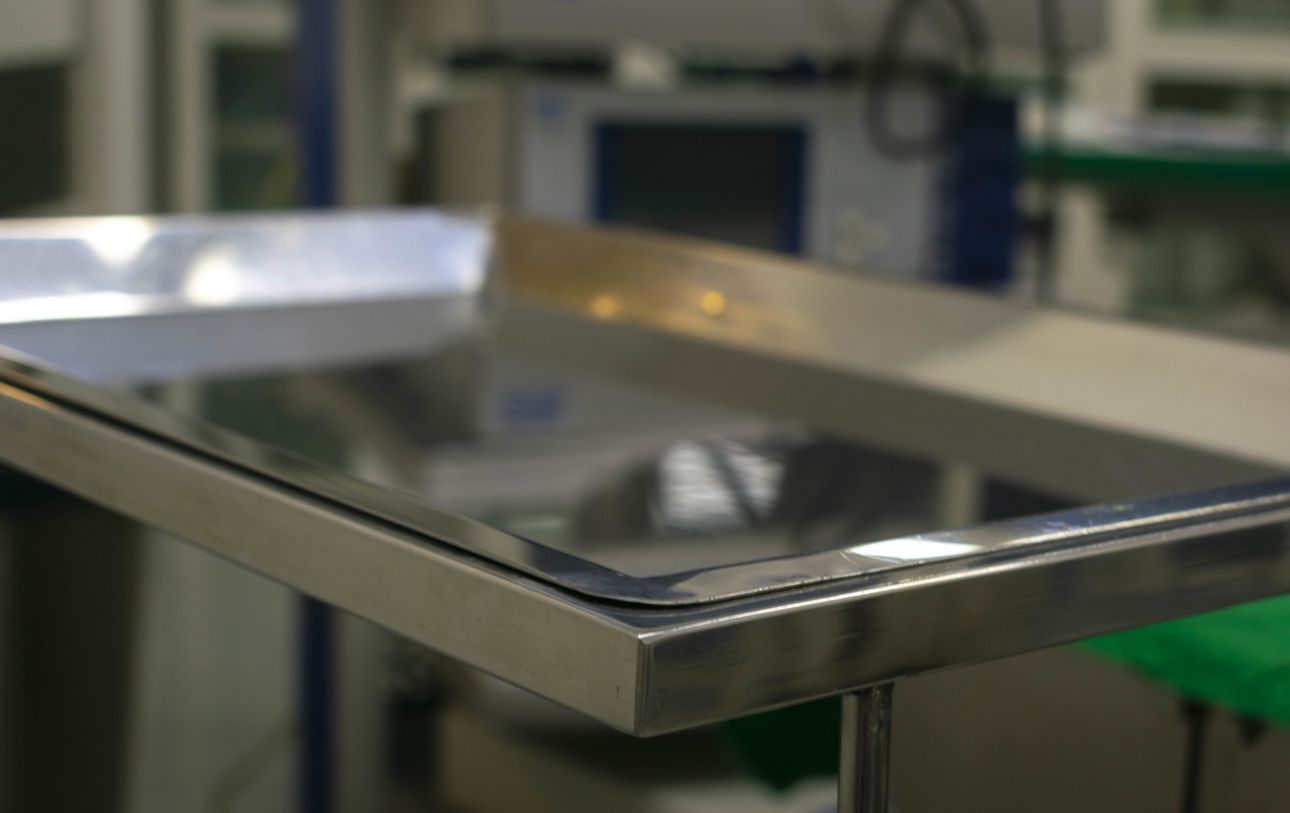

Stainless Steel for Outdoor Kitchens

As homeowners increasingly view their outdoor spaces as extensions of their living rooms, the outdoor kitchen has evolved from a simple grill setup to a full-fledged culinary and entertainment zone. At Silvey MetalWorks — where custom metal fabrication meets design and durability — we’re seeing three major trends rising to the top in 2025: premium stainless steel, elevated style, and lasting durability. Here’s what to know — and how you can apply it to your backyard in Chattanooga and beyond.

1. Stainless Steel: The Material of Choice

When it comes to outdoor cuisine, stainless steel remains king — and for very good reasons.

- High-quality stainless (especially grades like 304 or even 316) offers excellent corrosion resistance, making it ideal for outdoor exposure.Outdoorving+2hlposeybuilders.com

- It gives outdoor kitchens a sleek, modern look — couples beautifully with appliances, hoods, cabinetry, and even custom fabricated metalwork. hlposeybuilders.com+1

- For a custom metal-fabrication firm like Silvey MetalWorks, stainless steel opens up possibilities: welded frames, custom cabinet bodies, integrated drawers, door faces, and appliance framing all crafted to your space and specifications.

What to watch out for:

- Not all stainless steels perform the same outdoors. Lower grades (e.g., 430 or 201) are more prone to rust and damage in humid or coastal environments. RTA Outdoor Living

- Finish matters: polished stainless can reflect sunlight (and get hot), brushed or powder-coated finishes offer alternatives. RTA Outdoor Living

- As a Chattanooga-based project, local climate (humidity, seasonal temperature swings) should be factored in — choosing the right grade and proper fabrication (welds, gaskets, drainage) makes a difference.

At Silvey MetalWorks, we specialize in custom stainless steel fabrication for outdoor kitchens — from structural framing to bespoke drawer systems and access doors — ensuring the right material grade, finish and fabrication process for your unique space.

2. Style & Design: From Minimalist to Mixed Materials

The design of outdoor kitchens in 2025 is evolving fast — and not just in terms of appliances or layout, but in how the space integrates with the home and landscape.

Key design directions include:

- Modern-minimalist aesthetics: Clean lines, streamlined cabinetry, integrated appliances, neutral or monochrome palettes. One recent source notes: “In terms of style, 2025 is leaning towards sleek, minimalist outdoor kitchens with clean lines and neutral colors.” hlposeybuilders.com

- Mixed materials: Stainless steel being paired with natural textures (stone countertops, wood accents, tile backsplashes) to soften the industrial feel and bring warmth and visual interest. thedesignery.com+1

- Full-service outdoor kitchens: Beyond the grill — features like built-in bars, beverage stations, pizza ovens, outdoor refrigeration, fire features, comfortable lounge seating are all trending.

For homeowners in the Chattanooga area, this means your outdoor kitchen doesn’t have to be an afterthought — it can be a thoughtfully designed extension of your home’s architecture and your lifestyle. With custom metal fabrication, Silvey MetalWorks can help realize these design ambitions: custom stainless frames, tailored door/drawer configurations, unique finishes, and integration with stone, tile, or wood elements for a truly custom look.

3. Durability & Longevity: Building to Last

An outdoor kitchen is an investment — and one of the biggest concerns is ensuring it remains beautiful and functional year after year. Durability is more than a buzzword in 2025 — it’s central.

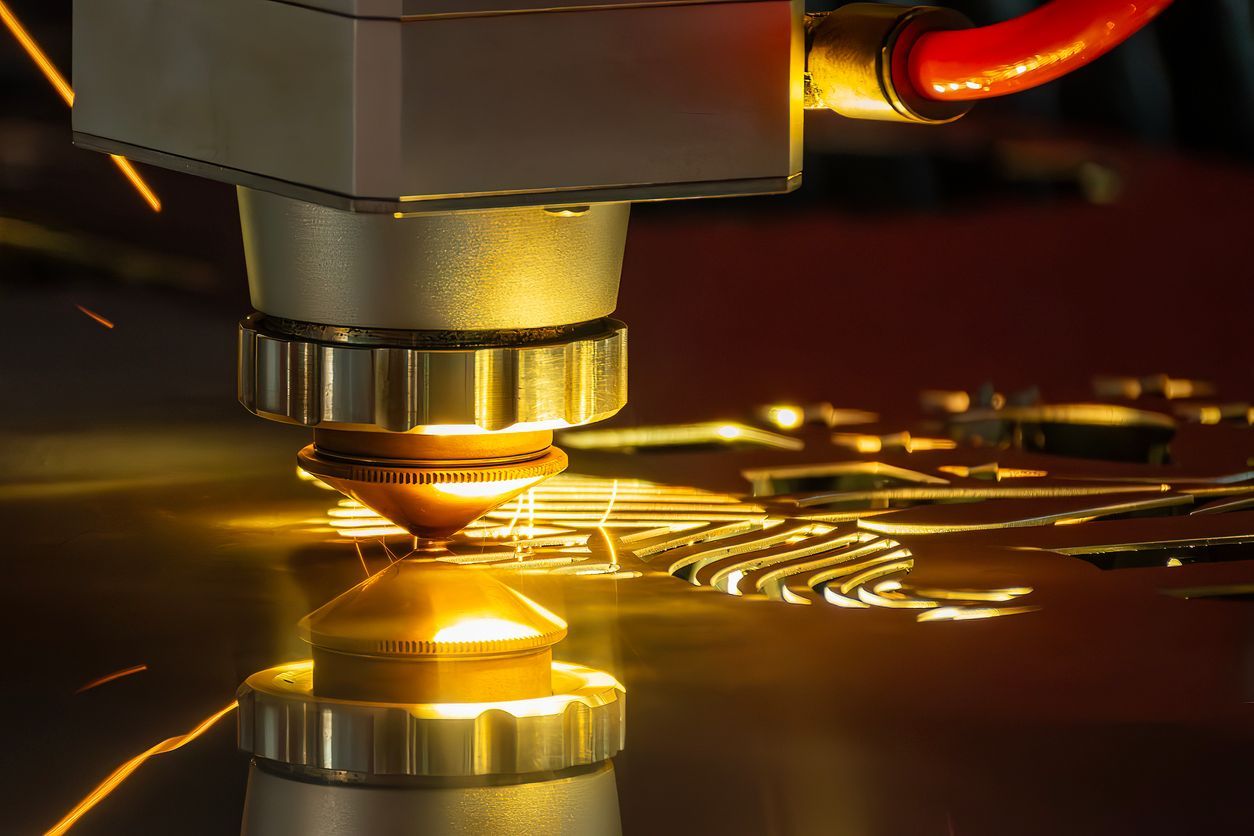

- Proper fabrication ensures things like drainage, weather-sealing, corrosion resistance, and robust joinery. For stainless steel outdoor kitchens, the grade, welding quality, and protective coatings matter a lot. RTA Outdoor Living

- Custom fabrication allows you to build for your climate and usage style. In Chattanooga’s climate — humid summers, seasonal rains — planning for high corrosion resistance and durable finishes is smart.

- Material-blend design (e.g., stainless steel paired with stone or tile) offers not just aesthetics but functional longevity: stainless supports the structure and appliances, stone and tile provide enduring surfaces.

- Maintenance should be realistic: high-grade stainless steel still needs care (cleaning, avoiding harsh chemicals, monitoring for dents/scratches) to maintain its look. As one guide notes: “Stainless steel is just more resistant than most other metals… However, it is still prone to dents and scratches.” RT

At Silvey MetalWorks, our custom fabrication processes are designed with durability in mind: we select appropriate stainless steel grades, finish welds cleanly, allow for thermal expansion/movement, and coordinate with cabinetry/appliance vendors to ensure long-term performance. We believe in building outdoor kitchens that aren’t just beautiful at installation — but that still perform beautifully for years to come.

4. Why Chattanooga Homeowners Should Choose Custom Fabrication

For homeowners in Chattanooga and the wider Tennessee region, fabricating your outdoor kitchen custom offers several advantages:

- Tailored to your space & vision: Rather than off-the-shelf modules, you get metalwork shaped precisely for your patio/patio roof, your grilling flow, your storage needs, and your finishing materials.

- Seamless integration: Custom fabrication means the stainless steel frames, doors, drawers, cabinet faces, and appliance housings can all be designed to match each other and integrate with your materials (stone, tile, wood).

- Durability optimized for local climate: We know local weather patterns, so we fabricate and finish with an eye toward our region’s humidity, temperature variation, and outdoor exposure.

- Higher perceived value and long-term enjoyment: Because you’re building specifically for you (and crafting quality), the end result often has better longevity, better aesthetics, and potentially better resale appeal.

By working with Silvey MetalWorks, you gain a partner who understands both the craft of metal fabrication and the design/cooking lifestyle of outdoor kitchens. Whether you want a sleek stainless outdoor cooking island, a built-in beverage station, or a full lounge-and-grill setup — we have the capabilities to bring that vision to life.

5. Planning Tips & Things to Consider

Here are some practical tips as you consider upgrading or installing your outdoor kitchen in 2025:

- Define your primary use: Will you mostly grill? Do you host big parties? Do you want a pizza oven or beverage bar? The layout and fabrication will differ accordingly.

- Select the stainless steel grade wisely: For outdoor use in Tennessee, we recommend going with at least 304 stainless steel — ensure the fabrication shop uses quality materials and finishes. RTA Outdoor Living

- Coordinate with appliances & cabinetry vendors early: The fabricated metal framework must integrate with grills, side burners, sinks, refrigeration, drawers, doors, etc. Designing all parts together avoids retroactive modifications.

- Think about material transitions: If you mix stone, tile, wood and stainless, plan for how these materials meet and move (expansion/contraction) so you avoid cracks, leaks or buckling.

- Plan for protection & coverage: Even stainless steel benefits from shade or overhead coverage (e.g., a pergola or roof) to protect from extreme sun/UV and help reduce heat/reflectivity issues.

- Maintenance plan: Agree on finish with your fabricator. Brushed or powder-coated options can reduce glare/hot-spots. Know how to maintain the stainless surface (cleaning, avoid abrasive tools, periodic inspection).

- Budget with value in mind: Custom fabrication and high-grade materials cost more upfront, but your outdoor kitchen becomes a lifestyle asset. A well-crafted stainless steel structure can last decades, delivering enjoyment and value.

2025’s outdoor kitchen trends underscore a shift: your backyard is no longer just a place for the occasional grill — it’s a fully-furnished, design-savvy and durable living space. With stainless steel as a backbone material, elevated style through design and mixed materials, and fabrication built to last, homeowners are creating backyards that rival indoor kitchens.

At Silvey MetalWorks in Chattanooga, we are passionate about helping homeowners bring these trends to life — not by following one-size-fits-all solutions, but by crafting custom metalwork that matches your vision, your home, and your lifestyle. If you’re considering an outdoor kitchen upgrade or new build, let’s talk about how stainless steel, smart design, and durable fabrication can come together to create a space you’ll enjoy for years.

Ready to explore your outdoor kitchen vision? Contact us at Silvey MetalWorks for a consultation, and let’s discuss how stainless steel fabrication, custom metalwork, and smart design can transform your backyard into your new favorite room.